Solution

SEND MESSAGE

Keeping in touch with us is a quick way tosolve your problem quickly

We have manual welding, robot welding, and multiple workstations are used at the same time. What type of dust removal equipment do we need?

Solution:

For relatively fixed welding points, a central dust removal system is generally used. Through point-to-point collection and centralized processing, it is connected to the end collection device through a pipeline. The collection device is generally a universal suction arm, a fixed suction device, a welding room, etc., and the discharge is 15 meters high, which meets environmental protection requirements.

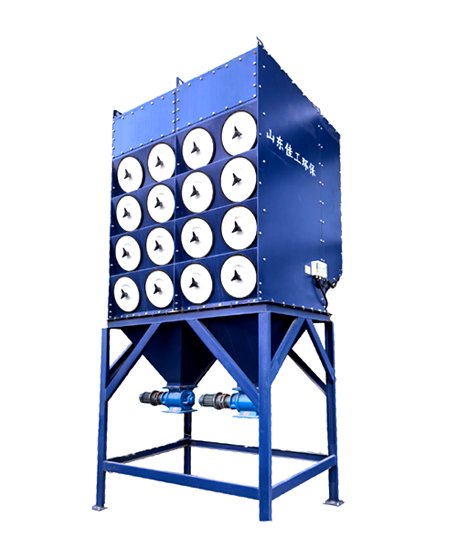

Central dust removal system:

01. Each suction arm is equipped with a regulating valve to facilitate air volume adjustment. Each workstation is controlled separately, which saves energy and reduces consumption, and saves costs.

02. Does not occupy space in the factory, and the overall layout is beautiful.

03. Adopts modular design, and can be configured according to customer site needs. N host machines can be assembled and used, with high cost performance.

04. The pulse backwash device cleans the filter cartridge to ensure that the equipment has a constant air volume and extend the service life of the filter cartridge.

What type of dust removal equipment is needed to solve the problems of large workpieces in the workshop, unstable welding points, workpieces need to be hoisted and turned, and it is inconvenient to install the suction arm?

Solution:

If there is no way to deal with it point-to-point, you can use the method of space management and adopt a self-circulating integrated machine. The industrial dust removal integrated machine adopts the principle of layered air supply and purification. The welding workshop is a workshop with a heat source and has a stable temperature gradient at height. Taking advantage of this feature, the industrial dust removal integrated machine equipment is designed to use the method of lower air supply and upper exhaust to deal with workshop smoke and dust, with advantages such as small footprint, free combination, single independent control, and convenient layout.

Industrial dust removal integrated machine:

01. Easy to install, only need to connect to power supply and compressed air.

02. Can be placed anywhere in the workshop, no pipeline installation is required, more convenient to move, and low installation cost.

03. The pulse backflush device cleans the filter cartridge to ensure that the equipment has a constant air volume and extend the service life of the filter cartridge.

04. Indoor circulation has little effect on the original temperature of the workshop.

05. Frequency conversion control, multi-speed adjustment, low power, large air volume, energy saving and power saving.